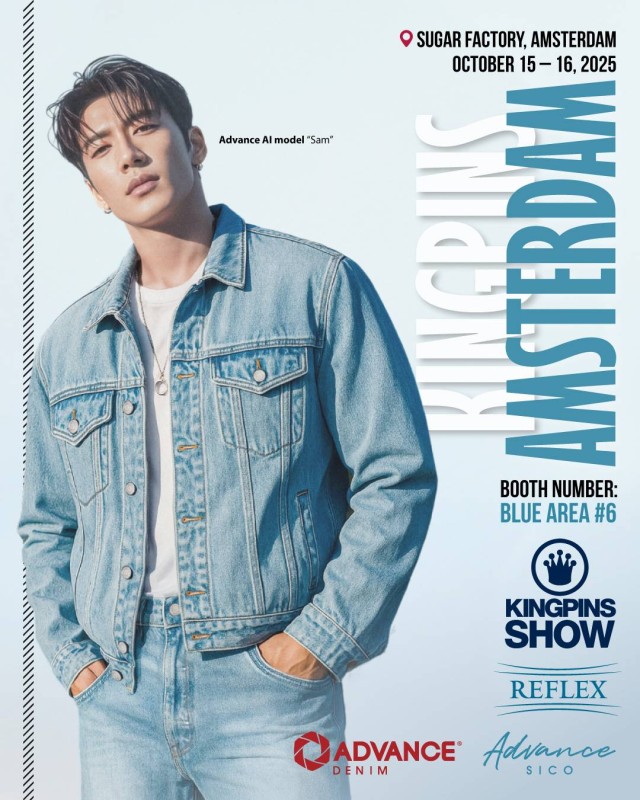

KINGPINS SHOW IN AMSTERDAM

15-16 October 2025

15-16 October 2025

Explore

KINGPINS SHOW IN AMSTERDAM

INTERTEXTILE SHANGHAI APPAREL FABRICS

2 - 4 September 2025

2 - 4 September 2025

Explore

INTERTEXTILE SHANGHAI APPAREL FABRICS

Denimsandjeans Vietnam Show 7th Edition

25 June 2025

25 June 2025

Explore

Denimsandjeans Vietnam Show 7th Edition

Kingpins Show in HangZhou China

22 May 2025

22 May 2025

Explore

Kingpins Show in HangZhou China

ADVANCE DENIM BLENDING HERITAGE WITH INNOVATION FOR A SUSTAINABLE FUTURE

26 May 2025

26 May 2025

Explore

ADVANCE DENIM BLENDING HERITAGE WITH INNOVATION FOR A SUSTAINABLE FUTURE

Advance Denim Stands Out as the Leader in Driving Wastewater Treatment Efforts

20 May 2025

20 May 2025

Explore

Advance Denim Stands Out as the Leader in Driving Wastewater Treatment Efforts

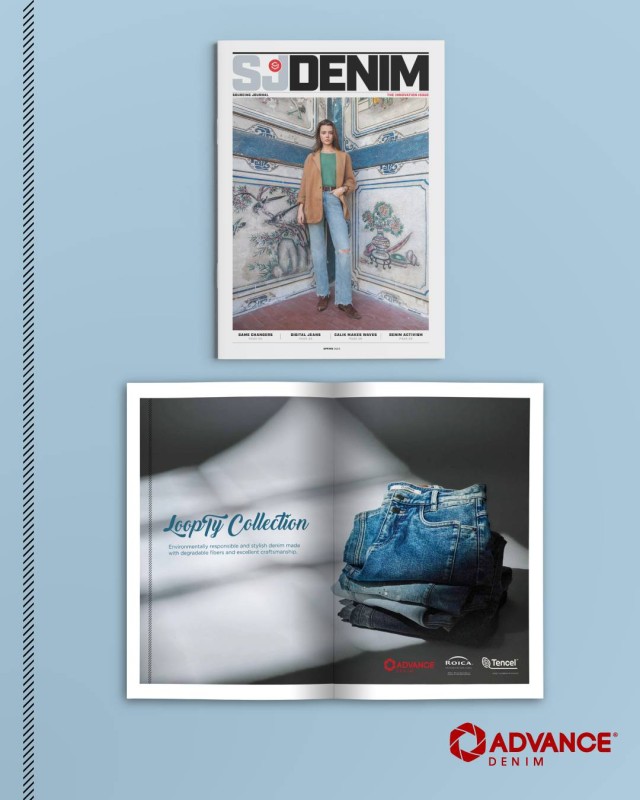

LoopTy Collection – A Collaborative Innovation by Advance Denim, ROICA™ & Lenzing

19 May 2025

19 May 2025

Explore

LoopTy Collection – A Collaborative Innovation by Advance Denim, ROICA™ & Lenzing

DENIM PREMIÈRE VISION IN MILAN

21 May 2025

21 May 2025

Explore

DENIM PREMIÈRE VISION IN MILAN

FASHION IN STYLE SHOW IN HONG KONG

26 April 2025

26 April 2025

Explore

FASHION IN STYLE SHOW IN HONG KONG

KINGPINS SHOW IN AMSTERDAM

16 April 2025

16 April 2025

Explore

KINGPINS SHOW IN AMSTERDAM

INTERTEXTILE SHANGHAI APPAREL FABRICS

11-13 March 2025

11-13 March 2025

Explore

INTERTEXTILE SHANGHAI APPAREL FABRICS

KINGPINS SHOW IN NEW YORK

17 January 2025

17 January 2025

Explore

KINGPINS SHOW IN NEW YORK

ADVANCE DENIM CUTTING -EDGE INNOVATIONS

14 November 2024

14 November 2024

Explore

ADVANCE DENIM CUTTING -EDGE INNOVATIONS

WeAr DENIM : Casual Fabrics and Sustainable Technologies

14 November 2024

14 November 2024

Explore

WeAr DENIM : Casual Fabrics and Sustainable Technologies

KINGPINS SHOW IN HONG KONG

21 November 2024

21 November 2024

Explore

KINGPINS SHOW IN HONG KONG

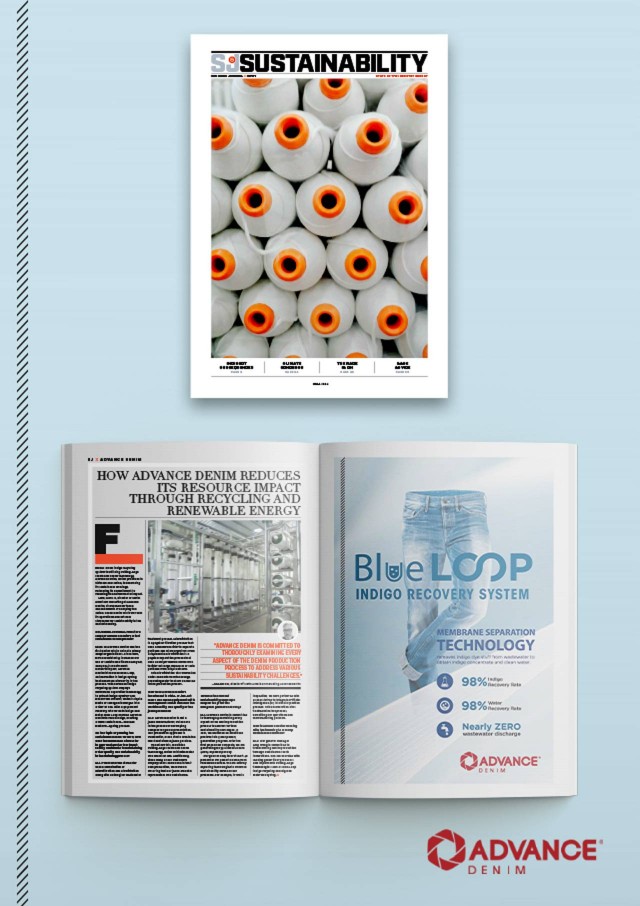

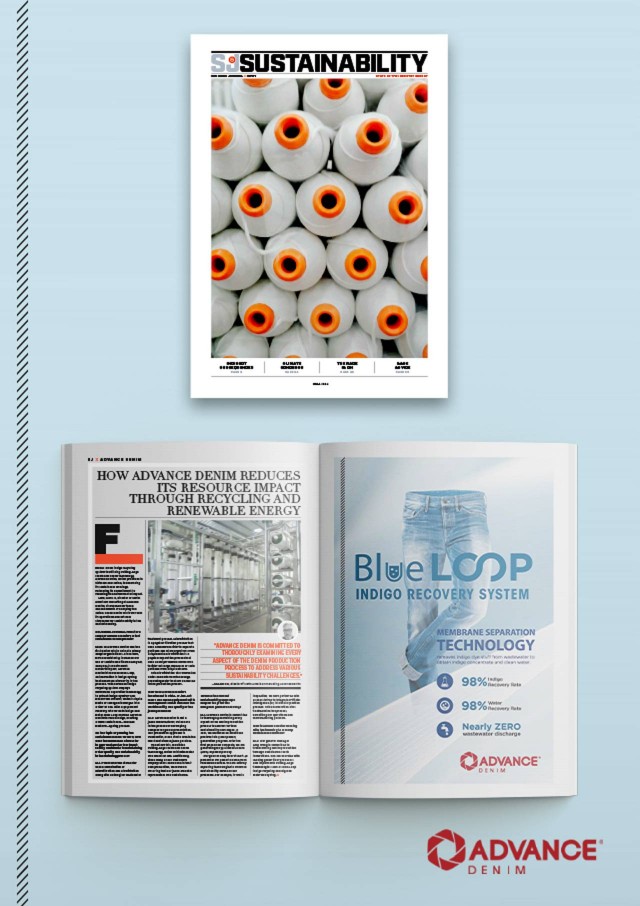

HOW ADVANCE DENIM REDUCES ITS RESOURCE IMPACT THROUGH RECYCLING AND RENEWABLE ENERGY

24 October 2024

24 October 2024

Explore

HOW ADVANCE DENIM REDUCES ITS RESOURCE IMPACT THROUGH RECYCLING AND RENEWABLE ENERGY

KINGPINS SHOW IN AMSTERDAM

17 October 2024

17 October 2024

Explore

KINGPINS SHOW IN AMSTERDAM

INTERTEXTILE SHANGHAI APPAREL FABRICS

24 August 2024

24 August 2024

Explore

INTERTEXTILE SHANGHAI APPAREL FABRICS

Advance Denim Collaborated with Denham to Develop TeamNL Kinetic Denim Uniform

19 July 2024

19 July 2024

Explore

Advance Denim Collaborated with Denham to Develop TeamNL Kinetic Denim Uniform

Advance Denim × Academy of Arts & Design,Tsinghua University Co-Designed Year of the Dragon Denim Bag

19 July 2024

19 July 2024

Explore

Advance Denim × Academy of Arts & Design,Tsinghua University Co-Designed Year of the Dragon Denim Bag

ADVANCE DENIM DELIVERS ‘TARGETED STRETCH’ WITH LAUNCH OF LYCRA FITSENSE® TECHNOLOGY

5 July 2024

5 July 2024

Explore

ADVANCE DENIM DELIVERS ‘TARGETED STRETCH’ WITH LAUNCH OF LYCRA FITSENSE® TECHNOLOGY

New Lycra Fitsense®️ Denim Technology

26 June 2024

26 June 2024

Explore

New Lycra Fitsense®️ Denim Technology

Denim and Jeans Show in Vietnam

20 June 2024

20 June 2024

Explore

Denim and Jeans Show in Vietnam

Future Fabrics Expo in London

19 June 2024

19 June 2024

Explore

Future Fabrics Expo in London

Limitless Design Solutions for Sustainable Denim

11 June 2024

11 June 2024

Explore

Limitless Design Solutions for Sustainable Denim

Happy Dragon Boat Festival

10 June 2024

10 June 2024

Explore

Happy Dragon Boat Festival

Denim Première Vision Show in Milan

1 June 2024

1 June 2024

Explore

Denim Première Vision Show in Milan

Kingpins Show in HangZhou China

20 May 2024

20 May 2024

Explore

Kingpins Show in HangZhou China

Embrace Imperfections Embrace Selvedge (Rivet Magazine)

20 April 2024

20 April 2024

Explore

Embrace Imperfections Embrace Selvedge (Rivet Magazine)

S/S 2024 IN SEASON DENIM LOOK BOOK (Rivet Magazine)

5 April 2024

5 April 2024

Explore

S/S 2024 IN SEASON DENIM LOOK BOOK (Rivet Magazine)

KINGPINS SHOW IN AMSTERDAM

17 April 2024

17 April 2024

Explore

KINGPINS SHOW IN AMSTERDAM

ADVANCE DENIM CONTINUES GLOBAL EXPANSION WITH NEW LOS ANGELES SHOWROOM (Rivet Magazine)

21 March 2024

21 March 2024

Explore

ADVANCE DENIM CONTINUES GLOBAL EXPANSION WITH NEW LOS ANGELES SHOWROOM (Rivet Magazine)

Advance Denim X Vivienne Tam

14 March 2024

14 March 2024

Explore

Advance Denim X Vivienne Tam

ADVANCE DENIM’S MATTE TENCEL™ COLLECTION

1 March 2024

1 March 2024

Explore

ADVANCE DENIM’S MATTE TENCEL™ COLLECTION

KINGPINS SHOW IN NEW YORK

24 January 2024

24 January 2024

Explore

KINGPINS SHOW IN NEW YORK

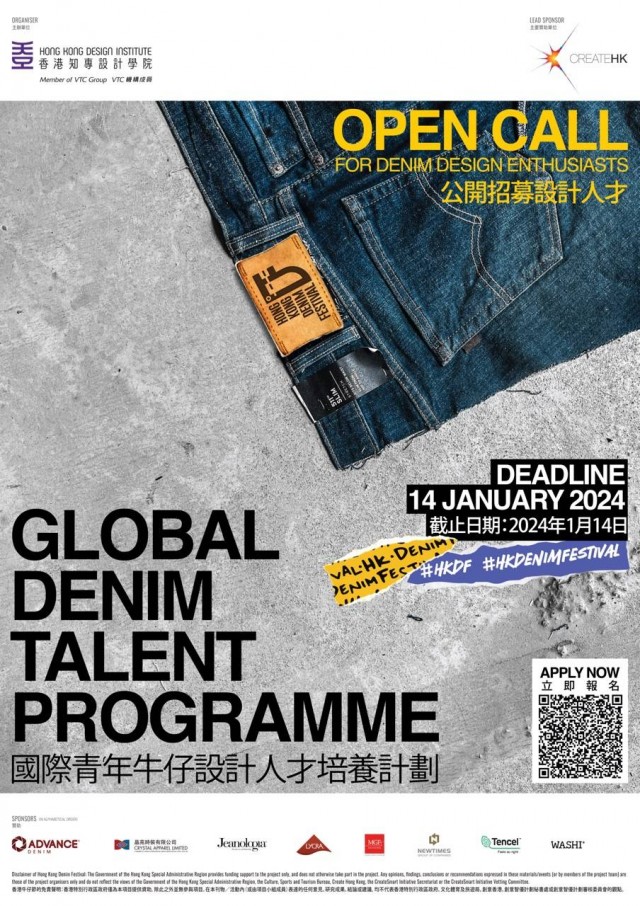

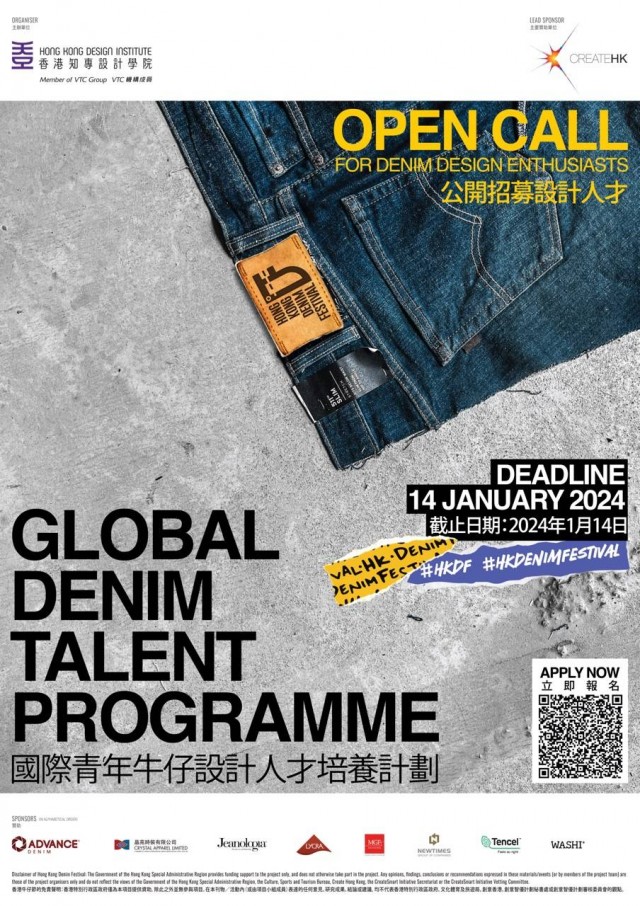

Global Denim Talent Programme

19 December 2023

19 December 2023

Explore

Global Denim Talent Programme

ADVANCE DENIM - AIR LOCK COLLECTION

18 December 2023

18 December 2023

Explore

ADVANCE DENIM - AIR LOCK COLLECTION

Denim Première Vision Show in Milan

22 November 2023

22 November 2023

Explore

Denim Première Vision Show in Milan

KINGPINS SHOW POP-UP IN HONG KONG

1 November 2023

1 November 2023

Explore

KINGPINS SHOW POP-UP IN HONG KONG

Hong Kong Denim Festival Opening Ceremony

1 November 2023

1 November 2023

Explore

Hong Kong Denim Festival Opening Ceremony

KINGPINS SHOW IN AMSTERDAM

12 October 2023

12 October 2023

Explore

KINGPINS SHOW IN AMSTERDAM

Intertextile Shanghai Apparel Fabrics

28 August 2023

28 August 2023

Explore

Intertextile Shanghai Apparel Fabrics

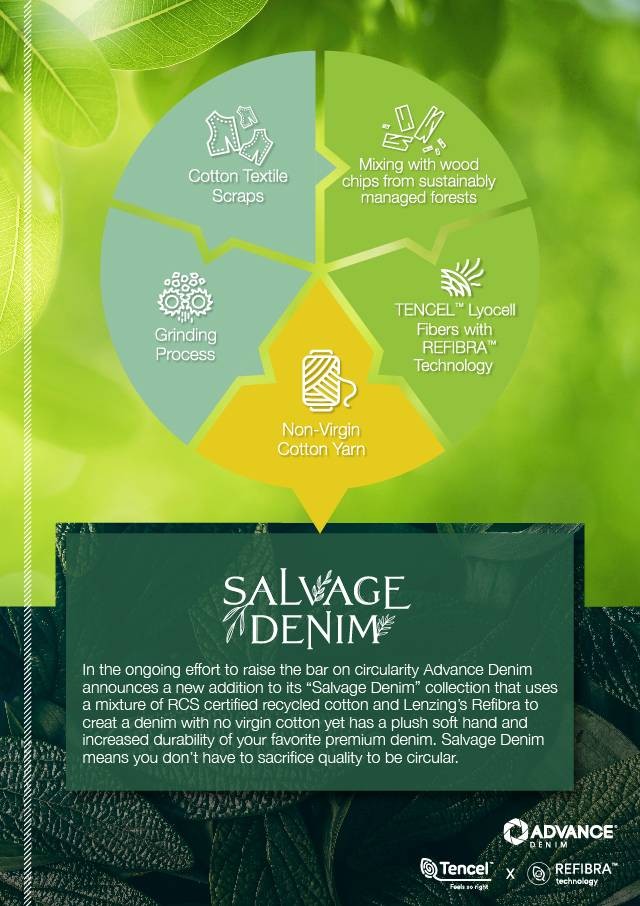

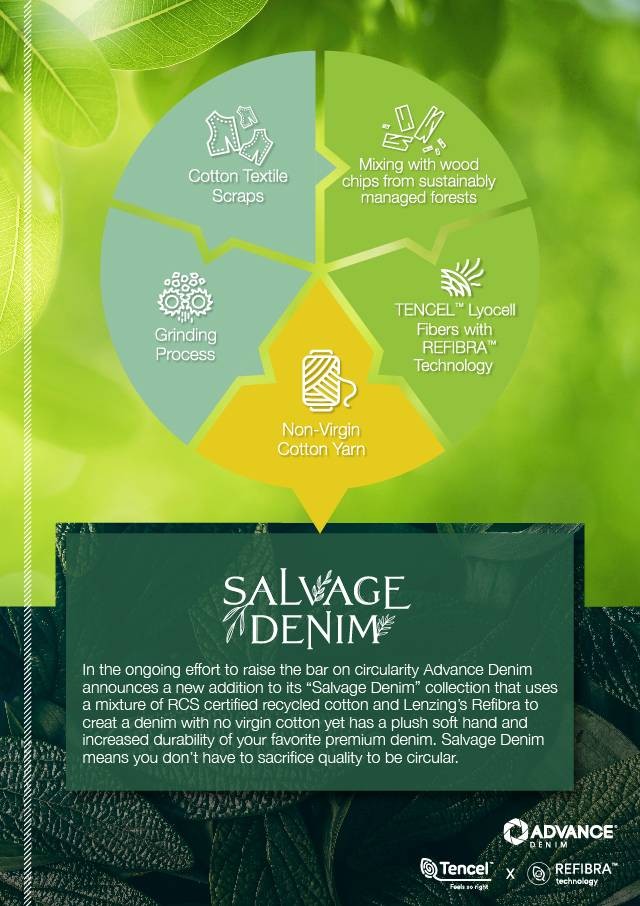

Salvage Denim (Non Virgin Cotton Yarn)

15 August 2023

15 August 2023

Explore

Salvage Denim (Non Virgin Cotton Yarn)

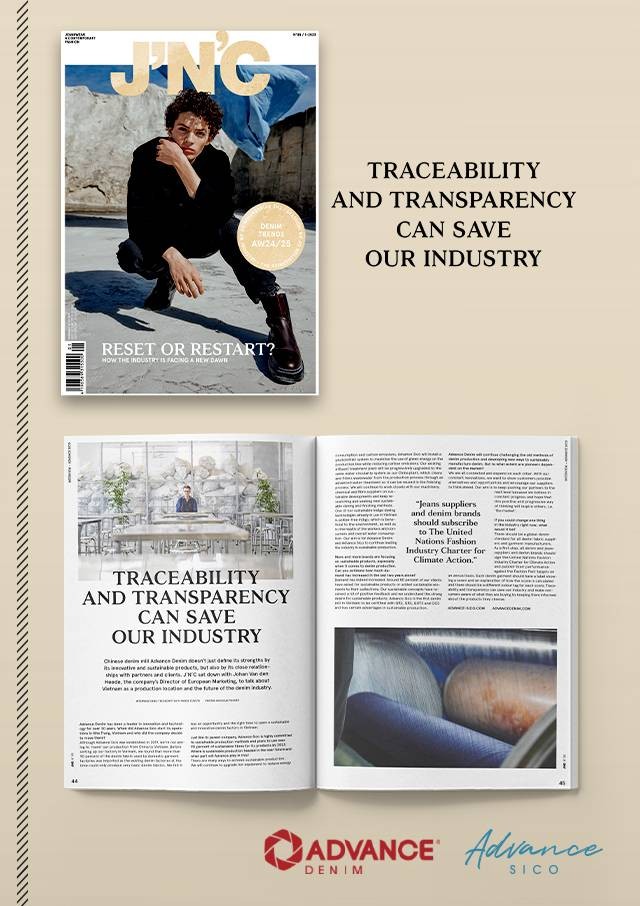

Traceability and Transparency Can Save Our Industry (J'N'C Magazine)

25 July 2023

25 July 2023

Explore

Traceability and Transparency Can Save Our Industry (J'N'C Magazine)

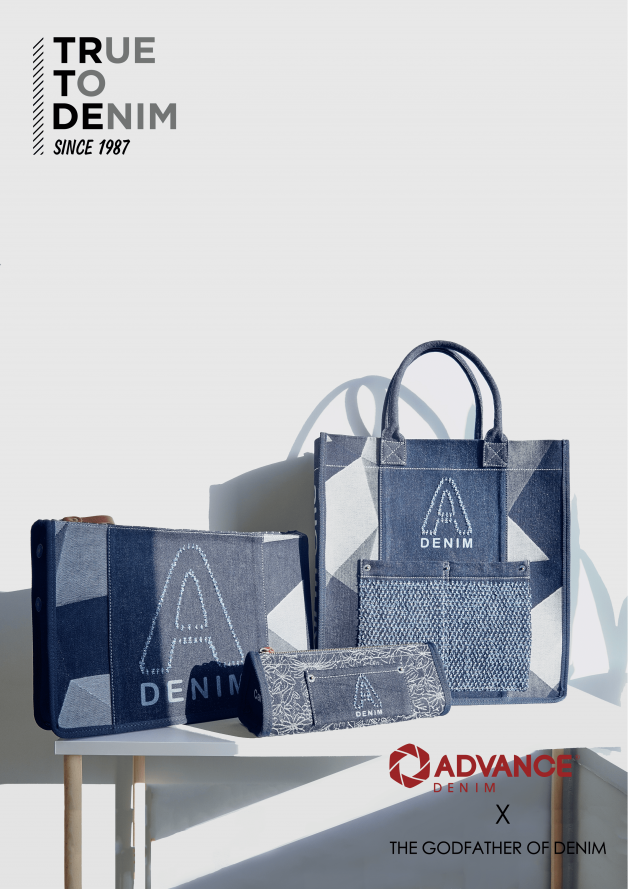

Advance Denim Collaborate with the Godfather of Denim to Create an Exclusive Collection of Denim Bags

19 July 2023

19 July 2023

Explore

Advance Denim Collaborate with the Godfather of Denim to Create an Exclusive Collection of Denim Bags

Supply Chain Partners to Add Character to Zero-Cotton Denim Fabrics

13 July 2023

13 July 2023

Explore

Supply Chain Partners to Add Character to Zero-Cotton Denim Fabrics

A new route forward (Inside Denim Magazine)

5 July 2023

5 July 2023

Explore

A new route forward (Inside Denim Magazine)

Future Fabrics Expo in London

26-28 June 2023

26-28 June 2023

Explore

Future Fabrics Expo in London

Best Product of The ISPO TEXTRENDS Spring and Summer 2025

20 June 2023

20 June 2023

Explore

Best Product of The ISPO TEXTRENDS Spring and Summer 2025

DENIM PREMIÈRE VISION SHOW IN BERLIN

28 May 2023

28 May 2023

Explore

DENIM PREMIÈRE VISION SHOW IN BERLIN

Advance Sico × Crystal Group

8 May 2023

8 May 2023

Explore

Advance Sico × Crystal Group

KINGPINS SHOW IN AMSTERDAM

12-13 April 2023

12-13 April 2023

Explore

KINGPINS SHOW IN AMSTERDAM

KINGPINS SHOW IN NEW YORK

11-12 January 2023

11-12 January 2023

Explore

KINGPINS SHOW IN NEW YORK

DENIM PREMIÈRE VISION SHOW IN MILAN

22 Nov 2022

22 Nov 2022

Explore

DENIM PREMIÈRE VISION SHOW IN MILAN

Functional Fabric Fair in Portland U.S

25 Oct 2022

25 Oct 2022

Explore

Functional Fabric Fair in Portland U.S

Denim Futures Conference & Showcase

20 Sep 2022

20 Sep 2022

Explore

Denim Futures Conference & Showcase

Blue Zone Denim Trade Show in Munich Germany

30 August 2022

30 August 2022

Explore

Blue Zone Denim Trade Show in Munich Germany

Outdoor Retailer Summer 2022 - Denver

8 June 2022

8 June 2022

Explore

Outdoor Retailer Summer 2022 - Denver

Denim Première Vision Show in Arena Berlin

14 May 2022

14 May 2022

Explore

Denim Première Vision Show in Arena Berlin

Kingpins Show in Amsterdam

20 April 2022

20 April 2022

Explore

Kingpins Show in Amsterdam

ADVANCE DENIM ESTABLISHES 10-YEAR CARBON REDUCTION PLAN

1 October 2021

1 October 2021

Explore